No Ignition or Failure to Start

A common issue with oil burners is when the unit fails to start or ignite, leaving the system inoperative. This can be due to a tripped safety switch, faulty thermostat, electrical failure, or lack of fuel. The first steps in troubleshooting should include checking the power supply at the circuit breaker, confirming the thermostat is calling for heat, and inspecting the reset button on the burner control. If the reset has tripped, press it once only — pressing it repeatedly can flood the combustion chamber with unburned oil, increasing the risk of a puffback.

Other potential causes include a clogged oil filter or nozzle, or a malfunctioning ignition system. The oil pump may not be delivering fuel correctly due to a vacuum issue or air in the line. The electrodes may be worn or misaligned, preventing spark formation. It’s also possible the cad cell sensor is dirty or defective, causing the burner to shut off prematurely. To fix the issue, clean or replace the nozzle, check and adjust the electrode position, replace the fuel filter if clogged, and inspect wiring for loose connections. If these steps don’t restore ignition, a certified technician should inspect the burner for deeper electrical or component failures.

Burner Runs but No Flame

If the oil burner’s motor runs but no flame is visible in the chamber, it often indicates a failure in the ignition or fuel delivery systems. This condition is serious, as unburned fuel may accumulate and lead to a dangerous puffback or even fire. Several causes are possible: a clogged or misaligned nozzle, weak spark from the ignition transformer, or air trapped in the fuel line. Burners that have recently run dry may have air pockets that need bleeding before normal operation resumes.

To resolve this, inspect and clean the electrodes, confirming their position and gap match manufacturer specifications. Replace the nozzle if it’s clogged or degraded. Test the ignition transformer for spark output — it should produce a strong, visible arc. Additionally, check the fuel supply system, including the filter, pump, and line fittings, for blockages or leaks. Bleeding the fuel line can restore flow and eliminate air. If a proper flame still doesn’t appear, the burner should be shut off and examined by a technician, as continued operation in this state may damage the unit or cause safety hazards.

Soot Buildup and Poor Combustion

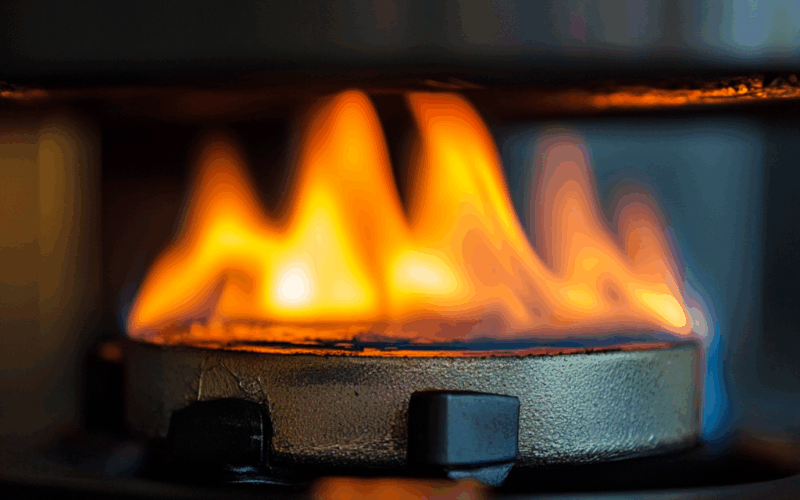

Heavy soot buildup and signs of incomplete combustion are common in neglected or poorly adjusted oil burners. This condition reduces heating efficiency and poses serious risks, including increased fuel usage, overheating, and carbon monoxide production. Soot forms when there is insufficient air for combustion, a dirty burner head, incorrect nozzle size, or improper fuel pressure. Visually, soot may be seen in the firebox, chimney, or on the heat exchanger surfaces.

To correct this issue, the burner requires a full cleaning and combustion adjustment. This includes cleaning the nozzle, inspecting and aligning the electrodes, adjusting the air shutter, and verifying fuel pressure with a gauge. A properly calibrated air-to-fuel ratio ensures complete combustion and minimal smoke. Technicians typically use combustion analyzers to measure draft, smoke number, CO₂, and stack temperature for precise tuning. Preventing soot buildup also means checking for proper draft conditions and ensuring the heat exchanger isn’t blocked or damaged. Regular annual maintenance is the most effective way to avoid this issue and keep the system running efficiently.

Irregular or Noisy Operation

Oil burners should run smoothly and quietly. If the system produces strange sounds — such as banging, humming, screeching, or rumbling — it’s usually a symptom of a mechanical or combustion-related problem. Loud bangs can result from delayed ignition, where unburned oil ignites suddenly. Humming or whining sounds often point to issues with the burner motor, fuel pump, or fan. Vibrations may stem from loose mounting or misaligned components.

To fix these problems, begin by tightening all visible screws and connections. Inspect the oil pump and motor for wear — unusual sounds may signal bearing failure or electrical imbalance. Check the flame for stability and correct color; a fluttering or yellow flame indicates improper draft or fuel supply. Noise during shutdown could be caused by a faulty solenoid valve or residual oil burning off. Draft regulators and barometric dampers should also be inspected for proper operation. Persistent or worsening noise should always be assessed by a heating professional, as it may lead to larger failures or unsafe operating conditions if left unresolved.

Oil Leaks and Fuel Supply Issues

Leaks in an oil heating system are not just a maintenance issue — they are a fire hazard and an environmental concern. Fuel oil leaks commonly originate from worn or cracked lines, loose fittings, defective pump seals, or old gaskets. Visible signs include oil spots on the floor, a persistent smell of oil, or a slow drop in fuel levels without corresponding system use. In some cases, small leaks may go unnoticed until they result in a system shutdown or contamination.

To fix and prevent leaks, inspect all visible fuel lines, especially flexible hoses near the burner. Tighten fittings as needed and replace aged or damaged lines with fire-rated alternatives. The filter canister and pump gasket should also be checked during each maintenance visit. In addition, problems like air intrusion or vacuum leaks can affect fuel delivery, leading to burner lockout or poor flame quality. Bleeding the line and testing the vacuum can help diagnose delivery issues. A strong preventive measure is to have the fuel system inspected at the start of each heating season to catch small issues before they escalate.

Electrical and Control System Failures

Modern oil burners rely heavily on a network of electrical components and safety controls to function reliably. When any part of this system malfunctions — whether it’s the thermostat, ignition control, safety switch, or wiring — the burner can stop working entirely or behave erratically. Electrical problems are often harder to diagnose because they may not show visible signs and can intermittently disrupt the system. These failures require systematic testing and a good understanding of burner circuitry.

Common steps to identify and address electrical and control system issues include:

- Verify Thermostat Functionality

Ensure the thermostat is set to a temperature higher than the current room temperature and is calling for heat. A faulty or miswired thermostat may fail to send the signal to the burner to start. - Check Power Supply and Breakers

Confirm that the system is receiving power. Inspect the circuit breaker panel for any tripped breakers and examine the emergency shut-off switch near the burner. - Inspect Burner Control and Safety Switches

Test the primary control, often located on or near the burner. If it has a reset button, press it once only. Examine high-limit switches, stack relays, and any other safety devices for proper operation and signs of tripping. - Test the Cad Cell Flame Sensor

The cad cell (flame detector) monitors whether a flame is present. If dirty or defective, it may cause the burner to shut down shortly after ignition, even if everything else is working. Clean or replace it if necessary. - Examine Wiring and Connections

Look for loose, corroded, or burned terminals, especially near high-heat components. Ensure all wire connections are secure and undamaged. Use a multimeter to confirm voltage at critical points in the system. - Replace Failed Components as Needed

If any part of the control system fails testing — such as a bad transformer, relay, or limit switch — replace it with an identical or manufacturer-approved part to ensure compatibility and safety.

Addressing electrical failures often requires patience and care, particularly when dealing with older systems or those that haven’t had routine servicing. These types of problems can be intermittent and may not trigger immediate visual symptoms. Because of the risks involved with live electrical systems and fuel ignition, it’s always recommended to contact a licensed heating technician if the cause isn’t immediately clear. Regular maintenance and annual tune-ups will help prevent control failures and extend the reliable lifespan of your burner.

Question and Answer

Answer 1: Common causes include a tripped safety switch, power issues, faulty thermostat, or a failed cad cell relay.

Answer 2: Check the ignition transformer, electrode positioning, clogged nozzle, and oil supply line.

Answer 3: Soot buildup is usually caused by poor combustion due to improper air-to-fuel ratio or dirty burner components.

Answer 4: Noises can result from delayed ignition, air in the fuel line, worn bearings, or draft system issues.

Answer 5: Regularly inspect and maintain fuel lines, replace worn parts, tighten fittings, and clean filters.